What is a 5-Layer Flexible Tube? A Game-Changer in Sunscreen Packaging

Packaging plays a crucial role in protecting cosmetic and pharmaceutical products from external factors like oxygen, moisture, and UV radiation. 5-layer flexible tubes have emerged as a superior solution, offering enhanced barrier protection for products like sunscreen, toothpaste, and skincare formulations. But what exactly is a 5-layer flexible tube, and how does it compare to other types of packaging? Let’s explore.

Outline

What is a 5-Layer Flexible Tube?

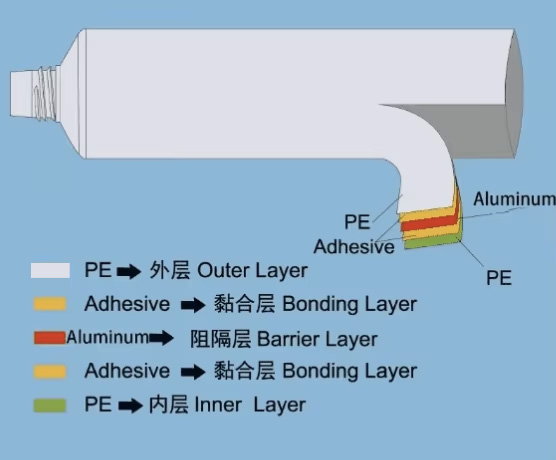

A 5-layer flexible tube is a multi-layered packaging solution that combines different materials to create a highly protective barrier against oxygen, moisture, and UV exposure. It typically consists of:

A 5-layer flexible tube is a multi-layered packaging solution that combines different materials to create a highly protective barrier against oxygen, moisture, and UV exposure. It typically consists of:

- Outer Layer – Provides durability and branding possibilities (often made of LDPE or HDPE).

- Adhesive Layer – Ensures strong bonding between layers.

- Barrier Layer (EVOH or Aluminum Foil) – Prevents oxidation and preserves active ingredients.

- Adhesive Layer – Additional bonding for structural integrity.

- Inner Layer – The product-contact layer, ensuring compatibility with the formula.

This structure makes 5-layer tubes particularly effective for sunscreen packaging, where maintaining the stability of UV filters is crucial.

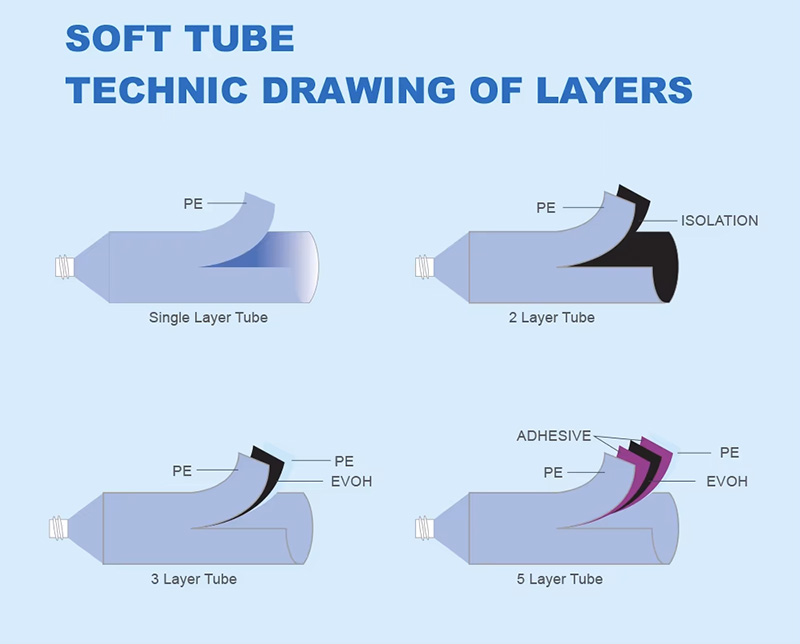

5-Layer Flexible Tube vs. Single-Layer and ABL Tubes: Key Differences

| Feature | Single-Layer Tube | ABL Tube (Aluminum Barrier Laminate) | 5-Layer Flexible Tube |

| Barrier Protection | Low – allows oxygen and moisture penetration. | High – aluminum layer provides strong barrier. | High – EVOH layer prevents oxidation and extends shelf life. |

| Squeezability | Very flexible and soft. | Less flexible due to aluminum. | Retains flexibility while offering better protection. |

| UV Resistance | Limited – can cause product degradation. | Moderate – aluminum blocks UV rays. | Excellent – EVOH effectively blocks UV rays. |

| Eco-Friendliness | Usually made of PE, recyclable but less durable. | Harder to recycle due to aluminum layer. | Some variations include PCR (Post-Consumer Recycled) materials for sustainability. |

| Application | Basic creams and lotions. | Toothpaste, pharmaceuticals. | Sunscreen, premium skincare, and sensitive formulations. |

Why These Differences Matter

For sunscreen packaging, barrier protection is critical. UV exposure and oxidation can degrade active ingredients, reducing the SPF effectiveness. 5-layer flexible tubes solve this issue by ensuring superior protection while maintaining the ease of use and premium feel.

Why 5-Layer Flexible Tubes are Ideal for Sunscreen Packaging

- Prevents Oxidation of Active Ingredients

- Sunscreens contain UV filters (e.g., avobenzone, oxybenzone) that are sensitive to oxygen and light. The EVOH barrier in 5-layer tubes helps prevent oxidation, preserving SPF stability.

- Enhances Product Shelf Life

- By blocking moisture and oxygen, these tubes extend the shelf life of sunscreen, reducing product waste and ensuring consistent performance over time.

- Combines Protection with Squeezability

- Unlike ABL tubes, which can be stiff, 5-layer tubes retain flexibility, making it easier for consumers to dispense the product smoothly.

- Eco-Friendly and Sustainable Options Available

- Some manufacturers offer PCR (Post-Consumer Recycled) versions, making them a more sustainable alternative to traditional laminated tubes.

- Premium Look and Feel for Branding

- The outer PE layer allows for high-quality printing, making 5-layer tubes visually appealing for premium sunscreen brands.

The Future of 5-Layer Flexible Tubes in Packaging

As sustainability becomes a top priority, 5-layer tubes are evolving to incorporate biodegradable materials, improved recyclability, and reduced plastic usage. The combination of barrier protection and flexibility makes them an industry standard for high-end skincare and sunscreen packaging.

Conclusion

5-layer flexible tubes outperform single-layer and aluminum laminate tubes in terms of barrier protection, durability, and user experience. For sunscreen packaging, they provide superior UV resistance, oxidation prevention, and long-lasting protection of active ingredients. As the demand for high-performance and sustainable packaging grows, 5-layer tubes will continue to shape the future of cosmetic packaging.

Are you looking for the best sunscreen packaging solution? Explore 5-layer flexible tubes to enhance your product’s performance, protection, and sustainability!