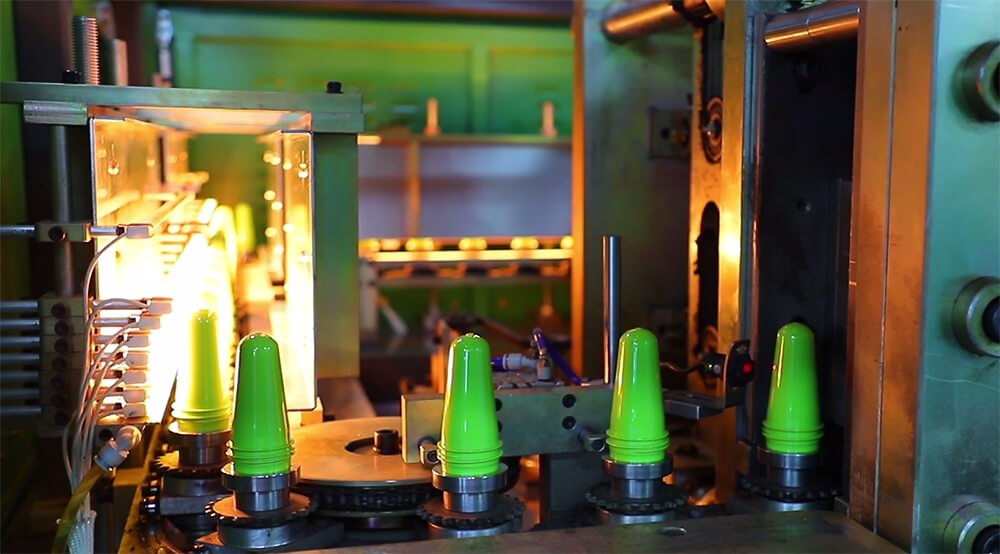

A cosmetic bottle may look simple on the outside, but its cost is the result of a series of intricate decisions. From material selection and mold development to printing techniques and final quality control, each step contributes to the total production cost. For decision-makers in the cosmetic industry, understanding these components is critical for cost forecasting, supplier negotiation, and maintaining healthy profit margins in a competitive market.

The typical cost structure of a cosmetic bottle includes raw material costs (30–40%), printing and decoration (20–35%), mold and design fees (5–10%), labor costs (around 15%), and quality control and warehousing (5%). The material type has the greatest influence on cost: PE is the most affordable, while acrylic is the most expensive. By optimizing material combinations and limiting surface treatments, brands can potentially reduce packaging expenses by over 30%.

In this article, we will examine each cost component in detail and provide insights on how to save money without compromising product quality or visual appeal.

What are the main cost components of a cosmetic bottle?

To effectively manage packaging expenses, it’s important to break down the cost structure into its primary parts:

Understanding this breakdown gives purchasing teams a foundation for accurate cost benchmarking and strategic supplier discussions.

What is the difference between PET and PETG in cosmetic packaging?

PET (polyethylene terephthalate) is widely used in cosmetic packaging due to its low cost, lightweight, and excellent transparency. It is especially favored for items such as toner bottles or lotion containers where clarity and rigidity are desirable.

PETG (glycol-modified PET), on the other hand, offers superior impact resistance, flexibility, and chemical resistance. This makes it more suitable for premium products or when the packaging needs to be squeezed or dropped without breaking. However, PETG tends to cost 10–20% more than standard PET due to its enhanced performance characteristics and slightly more complex processing requirements.

When choosing between PET and PETG, consider the product’s positioning, usage scenarios, and whether visual clarity or durability is more important.

How does acrylic compare to other materials in price and appearance?

Acrylic (also known as PMMA) is often chosen for its luxurious appearance that closely mimics glass. It offers excellent clarity, surface hardness, and a high-end tactile feel. As a result, it’s commonly used in packaging for premium skincare lines, serums, and prestige cosmetics.

However, acrylic comes with higher production costs—typically two to three times more expensive than PET or PP. It is also more prone to breakage during transit, requiring additional protective packaging which adds to shipping expenses. Moreover, it is less environmentally friendly and harder to recycle, which may conflict with sustainable packaging goals.

For brands targeting the luxury segment, acrylic can be justified. But for mass-market or mid-tier brands, PETG or AS may be more cost-effective alternatives offering similar visual appeal.

Is PP or PE the cheapest option for cosmetic bottles?

Among all plastic materials, PE (polyethylene) is often the most affordable option. It is lightweight, squeezable, and resistant to moisture, making it ideal for products like facial cleansers, body lotions, or shampoo bottles. Its soft touch also improves user experience in certain formulations.

PP (polypropylene) is slightly more expensive than PE but offers better resistance to heat and chemicals, which makes it suitable for products that require sterilization or higher shelf stability. On average, PP is about 15% cheaper than PET, while PE can be 20–30% cheaper.

Both PP and PE are excellent choices for cost-sensitive projects and are frequently used in personal care products where aesthetics can be simplified in favor of functionality.

Which plastic is most cost-effective overall for cosmetic packaging?

Each plastic type brings a different combination of cost, functionality, and appearance. Here’s a quick comparison:

The best choice depends on your brand’s goals. If cost-efficiency is key, combining PET for the bottle body with PP for the cap offers a solid balance of aesthetics and savings.

How much does printing and surface treatment affect the cost?

While decoration enhances a brand’s perceived value, it can quickly become a cost driver. Common surface treatments include:

The cumulative effect of multiple treatments can push total costs up by 20% or more. For budget-sensitive products, sticking to minimal screen printing is a smart move, especially on large-volume SKUs.

What are common cost traps in cosmetic bottle sourcing?

Even experienced procurement teams can fall into hidden cost traps:

To avoid these issues, always align internal design teams with manufacturing capabilities early, confirm mold specs before tooling, and negotiate realistic MOQ terms.

How can brands reduce packaging costs without compromising quality?

There are several proven strategies to lower packaging expenses without hurting your brand image:

By rethinking packaging holistically—not just visually—brands can trim 20–30% of costs while still delivering a premium unboxing experience.

Conclusion

Understanding the cost breakdown of a cosmetic bottle empowers decision-makers to optimize sourcing strategies, improve profitability, and minimize production risks. Whether you’re launching a new line or reworking an existing one, breaking down the numbers will always pay off. If you’re facing unique challenges in your packaging budget, feel free to reach out or share your thoughts—we’re here to help.