Why is PCR (Post-Consumer Recycled) becoming a game-changer in the cosmetics packaging industry? As a seasoned professional with two decades of experience in the field, I have witnessed a remarkable transformation in packaging practices. The growing urgency to address environmental concerns has led to a shift towards sustainable packaging solutions. In this article, we will delve into the world of PCR and explore why it has emerged as a pivotal concept in cosmetics packaging.

What drives the cosmetics industry to prioritize sustainability in packaging? In an era where eco-conscious consumers demand responsible practices, cosmetics brands are recognizing the need to align with these values. Packaging serves as a crucial touchpoint, shaping consumers’ perception and reinforcing a brand’s commitment to environmental stewardship.

How does PCR revolutionize the way we approach packaging? By recycling post-consumer cosmetic packaging waste, PCR presents an innovative and circular solution. It closes the loop by reducing reliance on virgin materials and tackling the pressing issue of plastic waste. Beyond waste reduction, PCR contributes to conserving natural resources, lowering carbon emissions, and promoting a more sustainable future.

What can we learn from successful applications of PCR in cosmetics packaging? Throughout this article, we will explore real-life examples of cosmetic brands that have embraced PCR. From innovative packaging designs to consumer responses, we will uncover the positive impact PCR can have on brand reputation and market positioning.

What challenges and solutions exist in implementing PCR? While PCR holds immense potential, it is not without its obstacles. Contamination issues, maintaining consistent quality, and creating robust infrastructure are some of the challenges that must be addressed. However, through collaborations and industry-wide initiatives, we can overcome these hurdles and unlock the full potential of PCR.

Why should stakeholders in the cosmetics industry embrace PCR? By embracing PCR, cosmetics companies can proactively contribute to a greener future. From reducing their environmental footprint to meeting consumer demands for sustainable products, PCR offers numerous advantages. It presents an opportunity for industry leaders to showcase their commitment to sustainability while creating positive change.

Together, let us embark on a journey through the world of PCR in cosmetics packaging. By understanding its significance and potential, we can collectively shape a more sustainable and responsible future for the cosmetics industry.

Contents

Definition and Process of PCR

What exactly is PCR and how does it work in the context of cosmetics packaging? Let’s explore the definition and the intricate process behind Post-Consumer Recycled materials.

Definition of PCR:

PCR, or Post-Consumer Recycled, are waste materials discarded by consumers, collected, processed, and transformed into new products. This recycling process helps reduce landfill waste, conserve resources, and save energy. Items like plastic bottles, aluminum cans, and paper products are sorted, cleaned, and repurposed into recycled paper, plastic lumber, and more. Post-consumer recycling emphasizes the reuse of materials that have served their initial purpose as consumer goods, contributing to environmental sustainability by reducing the need for raw materials extraction. Ultimately, post-consumer recycling promotes a circular economy, where waste is transformed into valuable resources for manufacturing new products.

The Recycling Process:

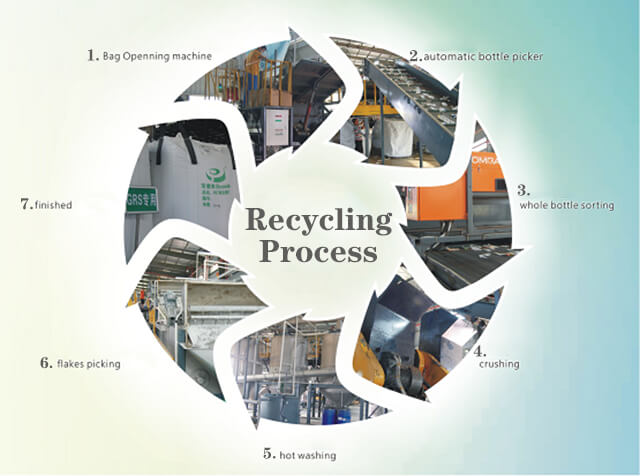

-

- Collection of post-consumer waste: The first step in the PCR process is the collection of used cosmetic packaging from consumers. This waste can come from a variety of sources, including recycling bins, waste management facilities, and dedicated collection programs.

- Sorting and separation of materials: Once collected, the waste is sorted and separated based on the type of packaging material. Plastics, glass, and other materials are segregated to ensure proper recycling.

- Cleaning and processing of recycled materials: The sorted materials then undergo thorough cleaning to remove any contaminants, such as labels, residual product, or other impurities. This cleaning process is essential to ensure the quality and safety of the recycled materials.

- Manufacturing new products using PCR materials: After cleaning, the recycled materials are processed and transformed into new packaging products. Depending on the specific requirements, the PCR materials can be used to create various packaging components, including bottles, jars, caps, and closures. These PCR packaging products can be customized to meet the specific needs and aesthetic preferences of cosmetic brands.

PCR offers a sustainable alternative to traditional packaging materials by reducing the reliance on virgin resources. By recycling and repurposing post-consumer waste, PCR helps close the loop in the packaging supply chain, minimizing waste and contributing to a more circular economy.

Next, we will explore the advantages of PCR, its common applications in the cosmetics industry, and the challenges and solutions associated with its implementation. Join me as we unravel the transformative potential of PCR in cosmetics packaging and discover how this innovative approach is shaping the future of sustainable beauty.

Advantages of PCR in Cosmetics Packaging

PCR in cosmetics packaging offers a multitude of advantages that contribute to both environmental sustainability and brand reputation. Let’s delve into the environmental and economic benefits that make PCR a compelling choice for cosmetic brands.

Environmental Benefits:

-

- Reduction of landfill waste: By recycling post-consumer cosmetic packaging waste through PCR, the amount of packaging material sent to landfills significantly decreases. This reduction alleviates the strain on waste management systems and helps combat the growing issue of waste accumulation.

- Conservation of natural resources: PCR reduces the demand for virgin materials, such as petroleum and minerals, which are commonly used in traditional packaging production. By utilizing recycled materials, valuable natural resources are conserved, reducing the need for extraction and minimizing the environmental impact associated with their extraction processes.

- Decreased energy consumption and greenhouse gas emissions: The production of PCR materials generally requires less energy compared to producing packaging materials from scratch. Additionally, using recycled materials in packaging reduces the carbon footprint associated with manufacturing processes, leading to decreased greenhouse gas emissions and mitigating climate change effects.

Economic Benefits:

- Cost-effectiveness for businesses: PCR offers potential cost savings for cosmetic brands. Utilizing recycled materials often comes at a lower cost compared to sourcing virgin materials. By incorporating PCR into their packaging strategies, companies can optimize their resource allocation and reduce expenses without compromising on quality.

- Creation of green jobs and economic growth: The adoption of PCR fosters the growth of the recycling industry and the development of new markets for recycled materials. This, in turn, leads to job creation and economic growth, supporting local communities and promoting a sustainable economy.

By embracing PCR in cosmetics packaging, brands can position themselves as leaders in environmental responsibility, appealing to a growing base of eco-conscious consumers. Incorporating sustainable practices and materials into their packaging strategy can enhance brand reputation, attracting loyal customers who prioritize sustainability in their purchasing decisions.

Moving on, we will explore the diverse applications of PCR in the cosmetics industry, demonstrating its versatility and adaptability across various packaging formats. Join me as we uncover the innovative ways in which PCR is reshaping the cosmetics packaging landscape and driving positive change in the beauty industry.

Development and Adoption of PCR in Cosmetics Packaging

The development and adoption of PCR (Post-Consumer Recycled) in cosmetics packaging have evolved significantly in response to the growing demand for sustainable solutions. Let’s explore the journey of PCR in the cosmetics industry, from its early stages to its widespread acceptance and industry-wide initiatives.

Early Stages of Sustainable Packaging in the Cosmetics Industry:

The cosmetics industry has been gradually transitioning towards sustainable packaging practices for several years. In the early stages, there was a focus on reducing packaging waste, optimizing material usage, and exploring eco-friendly alternatives. However, the advent of PCR introduced a revolutionary approach to sustainable packaging by incorporating recycled materials into the production process.

Evolution of Recycling Technologies for Cosmetic Packaging Materials:

Advancements in recycling technologies have played a crucial role in enabling the widespread adoption of PCR in cosmetics packaging. Innovations in sorting and cleaning processes have improved the quality and purity of recycled materials, making them suitable for use in high-quality packaging applications. This evolution has created new opportunities for cosmetic brands to integrate PCR into their packaging strategies.

Introduction of PCR as a Viable Solution:

As environmental consciousness grew, cosmetic brands began recognizing the potential of PCR as a viable solution for sustainable packaging. The use of PCR materials gained traction, driven by both consumer demand and brand initiatives to reduce their environmental impact. PCR offers a way to close the loop, transforming waste materials into valuable resources and aligning with the principles of a circular economy.

Increasing Adoption and Industry-wide Initiatives Supporting PCR:

The adoption of PCR in cosmetics packaging has gained momentum, with numerous brands embracing this sustainable approach. Cosmetic companies of all sizes are incorporating PCR materials into their packaging solutions, demonstrating their commitment to environmental stewardship. Additionally, industry associations, non-profit organizations, and regulatory bodies have launched initiatives to promote the use of PCR and provide guidance on best practices for its implementation.

Collaboration and Partnerships within the Cosmetics Industry:

The successful adoption of PCR in cosmetics packaging requires collaboration among various stakeholders. Cosmetic brands, packaging manufacturers, recycling facilities, and waste management entities are joining forces to develop robust recycling infrastructure, streamline supply chains, and ensure the availability of high-quality PCR materials. These collaborations facilitate the growth of PCR adoption and contribute to the establishment of industry-wide standards for sustainable packaging practices.

As the cosmetics industry continues to evolve, the development and adoption of PCR in packaging demonstrate its commitment to sustainability. By embracing PCR, cosmetic brands can not only meet the demands of environmentally conscious consumers but also contribute to a greener future. In the next section, we will delve into successful applications of PCR in cosmetics packaging, showcasing innovative and aesthetically appealing solutions that exemplify the potential of PCR in transforming the industry. Join me as we explore the exciting world of PCR in cosmetic packaging and discover the brands leading the way in sustainable beauty.

Successful Applications of PCR in Cosmetics Packaging

PCR (Post-Consumer Recycled) has paved the way for innovative and sustainable solutions in cosmetics packaging. Let’s explore some successful applications of PCR that have revolutionized the industry, offering both eco-friendly packaging and aesthetic appeal.

1. PCR Bottles and Jars:

Cosmetic brands have successfully incorporated PCR materials into the production of bottles and jars. PCR plastics, such as PET (Polyethylene Terephthalate) and HDPE (High-Density Polyethylene), can be transformed into sleek and durable packaging containers. These PCR bottles and jars not only reduce the demand for virgin plastic but also exhibit excellent quality and functionality, meeting the high standards expected in the cosmetics industry.

2. PCR Caps and Closures:

In addition to packaging containers, PCR materials have been utilized for caps and closures. PCR plastics can be molded into various shapes and sizes, providing secure and functional closures for cosmetic products. By using PCR caps and closures, cosmetic brands can maintain consistency in their packaging while minimizing the environmental impact.

3. PCR Paper and Cardboard Packaging:

PCR is not limited to plastics. Cosmetic brands have also embraced recycled paper and cardboard for packaging solutions. PCR paper and cardboard can be used for boxes, cartons, and inserts, providing an eco-friendly alternative to traditional paper packaging materials. These PCR paper-based solutions offer excellent printability and can be customized to showcase brand identity and product information effectively.

4. PCR in Luxury and Premium Cosmetics:

PCR has found its place even in the luxury and premium cosmetics segment. Brands committed to sustainability have successfully integrated PCR into their packaging, offering a combination of elegance and eco-consciousness. These premium PCR packaging solutions showcase the industry’s dedication to sustainable practices without compromising on the luxurious aesthetic and experience associated with high-end cosmetics.

5. Collaborative Initiatives and Limited Editions:

Collaborative initiatives and limited editions present exciting opportunities to showcase the potential of PCR in cosmetics packaging. Brands often partner with renowned artists, designers, or sustainability advocates to create special collections featuring PCR materials. These collaborations not only promote the importance of sustainable packaging but also generate enthusiasm among consumers, encouraging them to embrace eco-friendly options.

Successful applications of PCR in cosmetics packaging demonstrate that sustainable practices can be both environmentally responsible and visually appealing. By incorporating PCR materials, cosmetic brands can effectively communicate their commitment to sustainability, fostering brand loyalty among eco-conscious consumers.

In the next section, we will address the challenges associated with implementing PCR in cosmetics packaging and explore potential solutions. Join me as we navigate through these obstacles and discover how the industry can overcome them to further advance the adoption of PCR in cosmetics packaging.

Challenges and Limitations of PCR

While PCR (Post-Consumer Recycled) presents significant advantages and opportunities for cosmetics packaging, it is not without its challenges and limitations. Let’s explore some of the key obstacles that the industry faces in implementing PCR and discuss potential solutions to overcome them.

1. Contamination and Quality Control:

One of the primary challenges in PCR is the potential contamination of recycled materials. Despite sorting and cleaning processes, it is challenging to eliminate all impurities from post-consumer waste. Contamination can affect the quality and performance of PCR materials, posing difficulties in maintaining consistency and meeting regulatory requirements. To address this, implementing robust quality control measures, investing in advanced sorting technologies, and educating consumers about proper waste disposal can help minimize contamination issues.

2. Availability and Supply Chain:

PCR materials are reliant on the availability of post-consumer waste. Depending on the region and collection systems in place, the consistent supply of suitable PCR materials may be limited. Establishing efficient collection networks, collaborating with waste management entities, and promoting consumer awareness and participation in recycling programs can help ensure a steady supply of post-consumer waste for PCR.

3. Price and Cost-Effectiveness:

Compared to traditional packaging materials, PCR materials may carry a higher cost. The investment in recycling technologies and processing PCR materials can impact the overall price of PCR packaging solutions. However, as the demand for PCR increases, economies of scale and advancements in recycling technologies are expected to drive down costs. Additionally, companies can explore innovative business models and partnerships to overcome cost barriers and make PCR packaging more accessible.

4. Material Properties and Aesthetics:

PCR materials may exhibit different physical properties compared to virgin materials. This can pose challenges in terms of aesthetics, texture, and color matching, particularly for cosmetic brands that prioritize a consistent visual identity. By collaborating closely with packaging manufacturers and investing in research and development, brands can find innovative solutions to enhance the properties and appearance of PCR materials, ensuring they meet the desired standards.

5. Regulatory and Certification Requirements:

Meeting regulatory standards and obtaining necessary certifications for PCR materials can be a complex process. Compliance with regulations such as FDA (Food and Drug Administration) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is essential to ensure the safety and suitability of PCR materials for cosmetics packaging. Staying informed about evolving regulations, working closely with regulatory bodies, and obtaining necessary certifications are vital steps in overcoming these challenges.

While these challenges exist, they can be addressed through industry collaboration, technological advancements, and a collective commitment to sustainability. By actively addressing these limitations, the cosmetics industry can continue to advance the adoption of PCR, creating a more sustainable future for packaging.

Future Outlook and Opportunities

The future of cosmetics packaging lies in embracing sustainable practices, and PCR (Post-Consumer Recycled) plays a pivotal role in this transformation. As we look ahead, let’s consider the future outlook and opportunities that PCR presents for the cosmetics industry.

1. Advancements in Recycling Technologies:

Continued advancements in recycling technologies will drive the quality and efficiency of PCR materials. Innovations in sorting, cleaning, and processing techniques will enhance the purity and performance of recycled materials, making them even more suitable for cosmetics packaging. These advancements will expand the range of PCR materials available, offering increased flexibility and options for cosmetic brands.

2. Circular Economy and Closed-Loop Systems:

The concept of a circular economy, where resources are recycled and reused in a continuous loop, is gaining traction. PCR aligns perfectly with this vision by diverting waste from landfills and reintroducing it into the manufacturing process. The cosmetics industry has the opportunity to further develop closed-loop systems, ensuring that packaging materials are recycled and reincorporated into new packaging products, thus minimizing waste and reducing the environmental impact.

3. Consumer Education and Engagement:

Education and engagement of consumers are essential to drive the adoption of PCR and sustainable packaging practices. By raising awareness about the benefits of PCR and providing clear instructions on proper waste disposal, brands can empower consumers to make environmentally conscious choices. Communicating the brand’s commitment to sustainability and highlighting the use of PCR materials can resonate with consumers who prioritize eco-friendly products.

4. Collaboration and Industry-wide Initiatives:

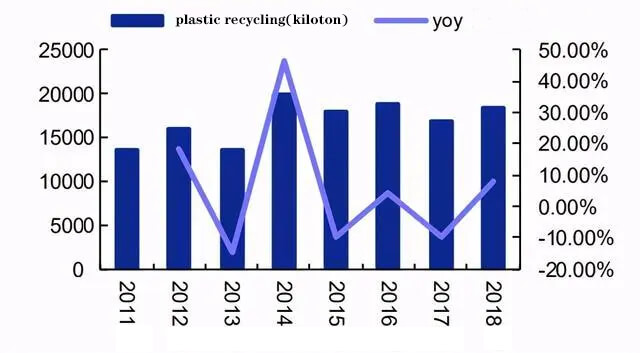

Plastic recycling in China recent years

Collaboration among cosmetic brands, packaging manufacturers, recycling facilities, and regulatory bodies will continue to be crucial for the successful integration of PCR. By sharing best practices, establishing industry standards, and investing in collective initiatives, the cosmetics industry can accelerate the adoption of PCR and drive systemic change. Collaboration also opens up opportunities for joint research and development, fostering innovation and creating sustainable packaging solutions.

5. Design Innovation and Aesthetic Appeal:

Incorporating PCR materials into cosmetics packaging offers endless possibilities for design innovation. Brands can explore creative approaches to make PCR packaging visually appealing, aligning with their brand identity and attracting consumers. The integration of PCR with other sustainable materials, such as biodegradable or compostable elements, can further enhance the environmental credentials of cosmetic packaging.

The future of cosmetics packaging is undoubtedly intertwined with the sustainable practices offered by PCR. As the industry continues to prioritize environmental responsibility, PCR will play a pivotal role in achieving sustainability goals. By addressing challenges, driving innovation, and fostering collaboration, the cosmetics industry can embrace the opportunities presented by PCR and pave the way for a greener and more sustainable future.

Conclusion

PCR (Post-Consumer Recycled) has transformed the cosmetics packaging industry, offering numerous benefits such as reduced landfill waste, resource conservation, and cost-effectiveness. Collaboration among brands, manufacturers, recycling facilities, and consumers is crucial for successful PCR adoption.

Advancements in recycling technologies, circular economy principles, education, collaboration, and design innovation will shape the future of PCR. By embracing PCR, cosmetic brands can demonstrate their commitment to sustainability, meet consumer expectations, and contribute to a greener future. Let us integrate PCR into our strategies, create positive environmental impacts, and pave the way for a sustainable beauty industry.

Together, we can inspire consumers, protect resources, and lead the movement towards sustainable beauty. Contact us for more information on PCR cosmetics packaging and products. Join us on this journey to shape a brighter and more sustainable future for the beauty industry.

Thank you for joining me on this journey through the world of PCR in cosmetics packaging. Xingyuan Plastic is a professional cosmetic packaging manufacturing company in China, we supply various PCR cosmetic packaging solutions for cosmetic brands. Feel free to contact us if you need information of PCR cosmetic packaging or products.